Reliable and Accurate Valve Selection for Pre-Lime and Milk-of-Lime Applications

At the ISSCT Congress 2025, researcher Sharum Iqbal delivered an insightful presentation titled “Reliable and accurate valve selection for pre-lime and milk-of-lime”, addressing a critical yet often overlooked issue in sugar processing operations—the choice of valves in the lime cycle.

Why Valve Selection in Lime Applications Matters

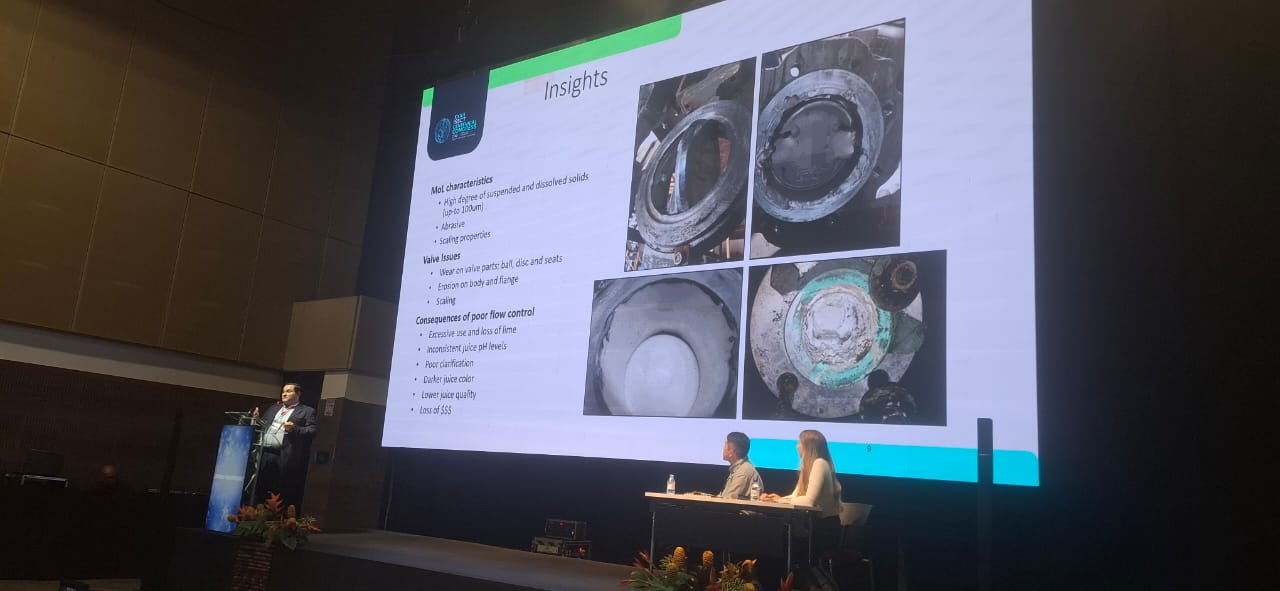

The lime cycle—converting quicklime (CaO) to milk-of-lime and controlling its flow—is fundamental for maintaining pH balance in sugar clarification. However, lime slurry is abrasive and sensitive to settling. Improper valve selection in this context can lead to:

- Premature wear and frequent maintenance

- Malfunctioning control loops and inaccurate pH regulation

- Elevated downtime and operational costs

Guidance from Slurry Valve Expertise

While Iqbal’s specific methods were not publicly documented, industry expertise in lime slurry applications suggests important selection criteria:

- Avoid standard valves not designed for abrasives; their use can drastically reduce reliability. For example, swapping to pinch valves doubled the mean time between failures in one case—cutting five-year operating maintenance costs from over $242,000 to about $55,000.

- Match valve design to slurry specifics—consider body construction, erosion-resistant seats, elastomer linings, and minimal voids to avoid blockage.

- Use a selection matrix evaluating isolation capability, throttling accuracy, maintenance needs, material compatibility, and slurry behavior. In other slurry systems, ball valves often rank highest overall, though local conditions like lime grit may favor other types.

Potential Insights from Iqbal’s Work

Based on the presentation title, Iqbal likely emphasized:

- Reliability-focused design—selecting valves that dependably operate with lime slurry under variable flow and pressure.

- Accuracy in control—key when metering lime for precise pH adjustment.

- Minimized operational disruption—valves that reduce maintenance frequency and simplify cleaning or replacement.

- Possibly proposing an evaluation framework or decision-support model customized for pre-lime and milk-of-lime lines, akin to approaches used in lime-storage modeling.

Why This Matters for Sugar Mills

Selecting the appropriate valves in lime applications is more than troubleshooting—it’s about optimizing process control, reducing waste, and improving reliability per cycle. Well-chosen valves can:

- Enhance chemical dosing precision

- Lower labor and maintenance costs

- Increase mill uptime and performance

Conceptual Takeaways

- Valve type selection matters: Avoid one-size-fits-all—match to slurry specifics.

- Balance reliability and control: Operators need both durability and precision.

- Structured evaluation helps: Consider performance, cost, maintenance, and slurry behavior in decisions.