Energy Savings with Dimple Tube Technology: Presentation by Darius Vicent Bezuidenhout at ISSCT

During the ISSCT Congress 2025 in Cali, South African researcher Darius Vicent Bezuidenhout (Sector Manager – Sugar Equipment, Bosch Projects) presented the paper “Energy savings utilising dimple tube technology”, showcasing practical and field results of an innovation designed to enhance heat transfer and improve the efficiency of heat exchangers used in sugar factories, particularly vacuum pans and similar equipment.

What is Dimple Tube Technology and Why It Matters

The technology consists of tubes with a dimpled geometry (small indentations) that increase the effective heat transfer surface area and create greater turbulence in the fluid boundary layer. According to the results presented:

- Increases heating surface area by approximately 15% compared to plain tubes in vacuum pan applications, resulting in higher heat transfer capacity.

- Improves turbulence and overall heat transfer coefficient, enabling shorter pan cycles and higher production per cycle.

- Is retrofit-friendly: the design is compatible with existing equipment, requiring minimal vessel or shell modifications, reducing investment and implementation time compared to more disruptive alternatives.

Reported Operational Results and Benefits

The presentation detailed plant and field trial results showing tangible benefits: reduced vacuum pan cycle times, increased pan floor capacity, and consequently energy savings and lower operating costs. Preliminary data and validation tests suggest the technology offers a favorable cost/benefit ratio compared to other capacity improvement methods.

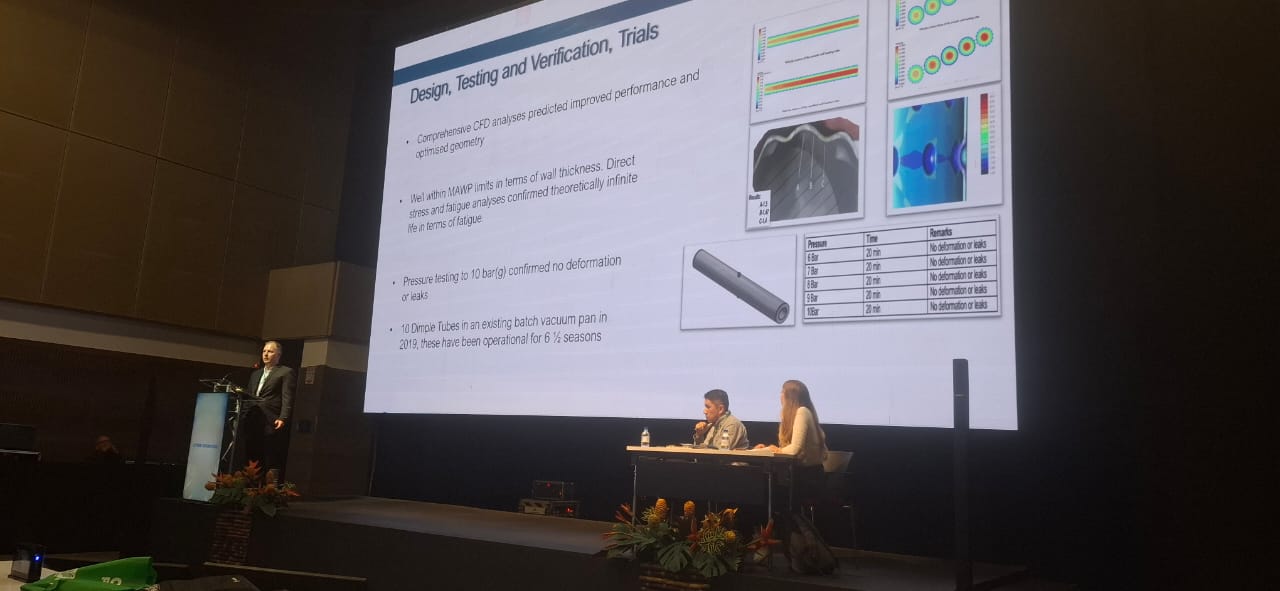

Development, Testing, and Commercial Status

The initiative originated within Bosch Projects’ R&D division; the design has undergone development, laboratory testing, and real-world trials to deliver a patent-pending, market-ready solution. Technical briefs and industry notes emphasize that this option provides a quick-to-implement pathway for sugar mills seeking to boost performance without major capital projects.

Applications Beyond Sugar Mills

While initially motivated by the need to optimize vacuum pans in the sugar industry, the dimple tube approach can be applied to shell-and-tube heat exchangers in chemical, petrochemical, food, and energy recovery sectors where improved heat transfer and reduced thermal consumption are critical. Academic studies and technical reviews support the use of dimpled surfaces for energy savings across various thermal systems.

About the Presenter and Team

Darius Vicent Bezuidenhout serves as Sector Manager for Sugar Equipment at Bosch Projects / Bosch Holdings and has spearheaded, alongside colleagues such as Meethan Gokool and Murray Stevens, the research, development, and field implementation of the solution. His contributions combine applied process engineering, on-site testing, and product commercialization strategies.

Conclusion and Relevance for the Cane Sugar Industry

Bezuidenhout’s presentation at ISSCT highlights a practical, low-disruption route for mills to increase capacity and efficiency: better thermal surface design instead of costly expansions or complex replacements. For plants handling large volumes and relying on pan and evaporation cycles, adopting dimple tube technology can deliver quick operational improvements, financially attractive returns, and significant reductions in steam/fuel consumption.