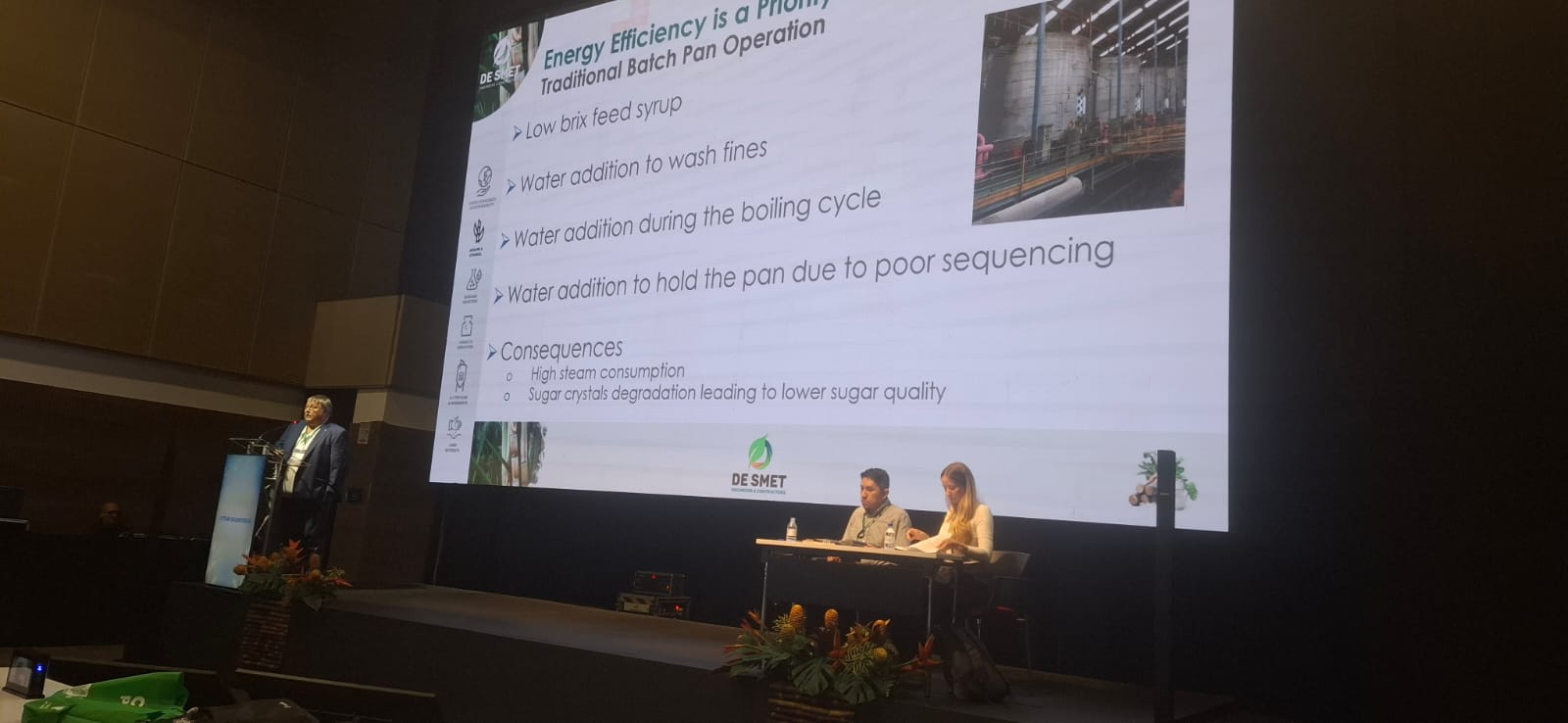

Batch Pan Automation: Energy Savings and Sugar Quality Improvements

At the ISSCT Congress 2025, Belgian researcher Marc Vandemoortele informed attendees on how batch pan automation delivers both significant energy savings and improvements in sugar quality—establishing its role as a cornerstone of modern sugar factory efficiency.

Why Automating Batch Vacuum Pans Matters

- Energy hogs of the sugarhouse: Traditional batch pans—critical for sucrose crystallization—consume large amounts of steam, especially when operators manually add water to control fines and crystal size. These water additions can account for an extra 2–16% of exhaust steam per ton of cane, drastically raising energy needs.

- Steam savings potential: Automation systems can eliminate or drastically reduce water additions, leading to steam savings within that same 2–16% range.

How Automation Enhances Sugar Quality and Output

- Controlled crystallization: Automated control of key parameters—like supersaturation, seed addition, and boiling profiles—prevents uncontrolled secondary nucleation, ensuring uniform crystal growth and reducing fines. This yields higher crystal content and better overall sugar quality.

- Capacity maximization & smoother operations: Automation enables synchronization of pans with feed tank levels and steam availability, smoothing out batch cycles, minimizing downtime, and improving throughput.

- Energy-efficient pasteurization: By maintaining ideal crystallization conditions, automation can allow the use of lower-pressure vapors (e.g., 3rd or 4th vapor stages) and reduce reliance on high-energy steam, optimizing the plant’s energy balance.

Key Benefits at a Glance

| Category | Impact of Batch Pan Automation |

|---|---|

| Energy Efficiency | Reduces or eliminates water-induced steam losses (2–16%) |

| Sugar Quality | Enhances crystal uniformity and reduces fines |

| Operational Capacity | Enables smoother, faster batch cycles and higher throughput |

| Resource Optimization | Allows use of low-pressure vapor and reduces energy load |

Conclusion

Marc Vandemoortele’s presentation underscored the transformative potential of batch pan automation. In sugar houses where traditional practices remain, automation offers a clear path to lower energy costs, superior sugar quality, and operational excellence—all while streamlining the crystallization process with precision.