Assessing the Impact of Evaporator Station Configuration on the Feasibility of Greenfield Cane Factory Projects

At ISSCT Congress 2025, researcher Omkar P. Thaval, based in Germany, presented the findings of his study entitled “Assessing the Impact of Evaporator Station Configuration on the Feasibility of Greenfield Cane Factory Projects.” His work highlights how the configuration of the evaporator station directly influences the technical, economic, and energy viability of new (greenfield) sugar factory projects.

Why is evaporator station configuration so critical?

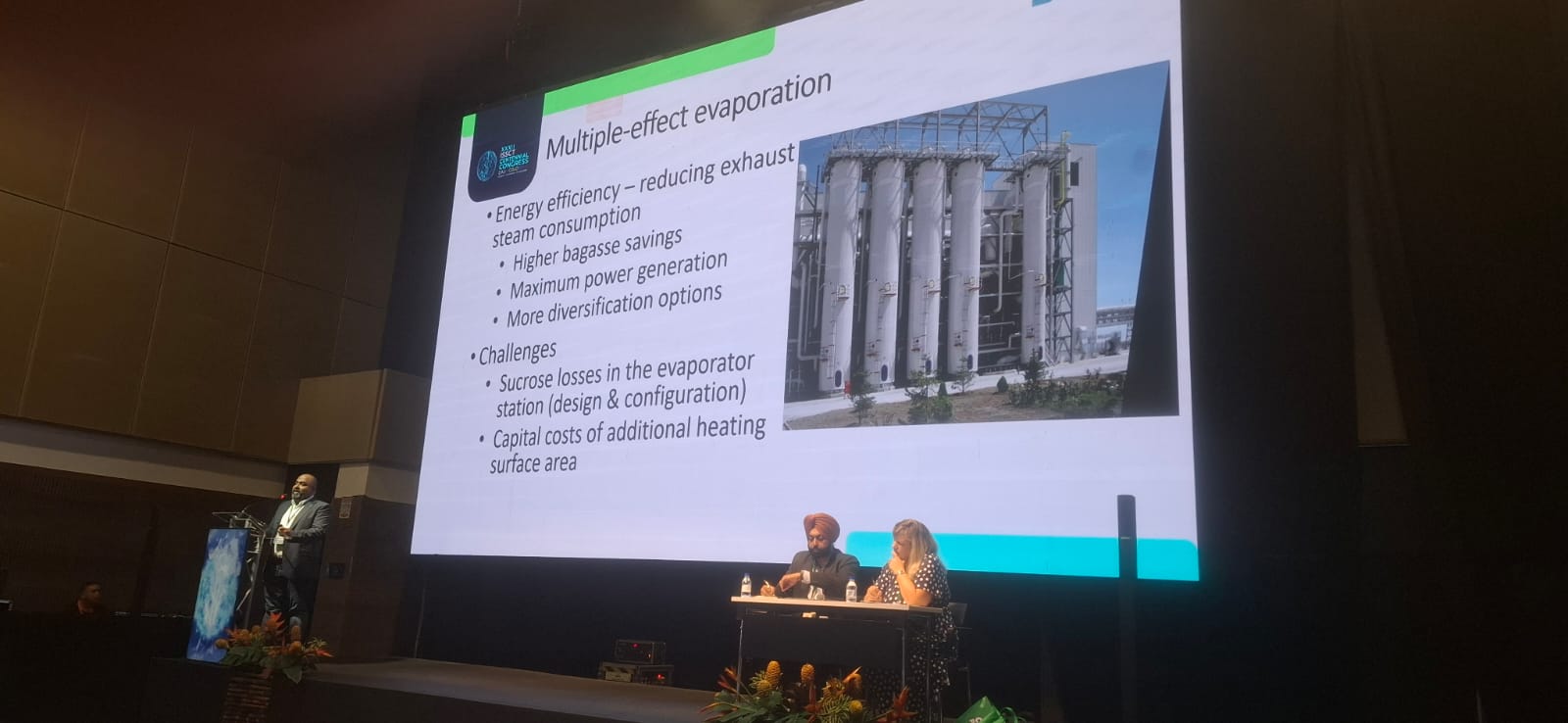

The evaporator is one of the largest energy consumers in a cane sugar factory due to the extensive use of steam in juice concentration. For greenfield plants, designing an optimal evaporator station not only reduces operational costs but also impacts profitability, cogeneration potential, and overall capital investment.

Key aspects addressed in the presentation

The presentation likely included:

- Configuration types: The number of effects (double, triple, quadruple, quintuple, etc.) and system architecture (conventional, falling film) have a direct impact on thermodynamic efficiency and capital costs.

- Thermal efficiency and steam consumption: According to technical literature, increasing the number of effects or adopting falling-film evaporation can cut bagasse use by as much as 30–40%, depending on the configuration strategy. These energy savings are essential to feasibility assessments.

- Cost-benefit in greenfield projects: The balance between higher upfront investment for advanced evaporator systems and lower long-term operating costs is critical. In cogeneration scenarios, achieving steam-on-cane ratios below 40% is often a make-or-break factor for project viability.

- Integrated analysis: Thaval likely relied on simulation models (such as SysCAD or similar tools) to evaluate how different configurations affect overall plant performance—an approach commonly used to optimize “steam on cane” in modern mills.

Probable methodology

The study likely combined:

- Configuration design: Defining alternatives (e.g., triple vs. quintuple effect setups) and technology options.

- Operational simulation: Modeling steam use, yield, cost impacts, and potential cogeneration income.

- Scenario comparison: Weighing investment costs, fuel/bagasse consumption, power export potential, and ROI.

- Practical recommendations: Concrete guidance for new factory designers on optimal configuration and cost-benefit balance.

Why this matters for new projects

For engineers and investors planning new greenfield sugar mills:

- A well-configured evaporator station can make the difference between a viable and a non-viable project.

- Reduced steam demand lowers operational costs and frees up energy for cogeneration or refinery operations.

- Choosing the right number of effects and technology (e.g., falling-film) can significantly improve cost-benefit ratios and accelerate return on investment.