Applexion — Leading Purification for Next-Gen Sugar Processing

At the ISSCT Congress 2025, Applexion distinguished itself by showcasing advanced purification technologies that elevate sugar processing efficiency, product quality, and sustainability. Specializing in chromatography, ion exchange, and membrane filtration, Applexion delivers turnkey, performance-driven solutions—particularly valuable for cane sugar mills refining for food ingredients and value-added products.

Technologies Powering Efficient, High-Quality Sugar Processing

- Chromatography & Ion Exchange

Applexion offers decolorization systems and resin-based purification built for high throughput and lower OPEX. Their continuous chromatography and resin recovery designs optimize resin use and minimize water/regenerant consumption—streamlining sugar refining operations. - Membrane Filtration — including NAP Microfiltration

Their NAP™ microfiltration process transforms clarified cane juice, enabling the production of VHP (Very High Polarization) sugar without sulfitation—delivering up to 40% less color, 55% ash reduction, and a 20% speed boost in crystallization. - Applexion™ CSF Process

This integrated filtration and softening approach removes salts before evaporation, reducing scale formation and enhancing crystal yield in pans. - Liquid Sugar Lines

Applexion enables parallel production of high-purity liquid sugar directly from decolorized liquor—without altering the sugar house layout, avoiding extra molasses, and flexibly balancing crystalline and liquid sugar output.

Sustainability and Digital Innovation

- Green Performance Boosts

Through services like Run 4.0, Perform 4.0, and Link 4.0, Applexion helps mills monitor and optimize operations, lowering water and energy use while improving throughput. - Carbon Footprint Reduction

The company integrates CO₂-e estimations into quotations and optimizes regeneration systems (e.g., nanofiltration-based brine recovery) to reduce resin and chemical waste, aligning with sustainability goals. - Decades of Expertise, Worldwide Reach

Founded in 1968, Applexion has over 50 years of R&D on purification systems, 800+ units delivered globally, and teams supporting food, fermentation, bio-based, and agro-industrial markets.

Why Sugar Producers Should Consider Applexion

| Benefit | Impact |

|---|---|

| Higher sugar purity | Improved color, lower ash, better crystallization |

| Lower operating costs | Less water, chemicals, and energy use |

| Process flexibility | Produce liquid sugar alongside crystalline output |

| Sustainability | Reduced chemical waste and emissions via smart regeneration |

| Long-term support | Global service network, consumables supply, and digital tools |

Contact Applexion for Cutting-Edge Sugar Purification

Head Office – Lyon, France

5 Chemin du Pilon, Saint-Maurice-de-Beynost, 01700 Lyon

Phone: +33 4 00 00 00 00

Website: applexion.com

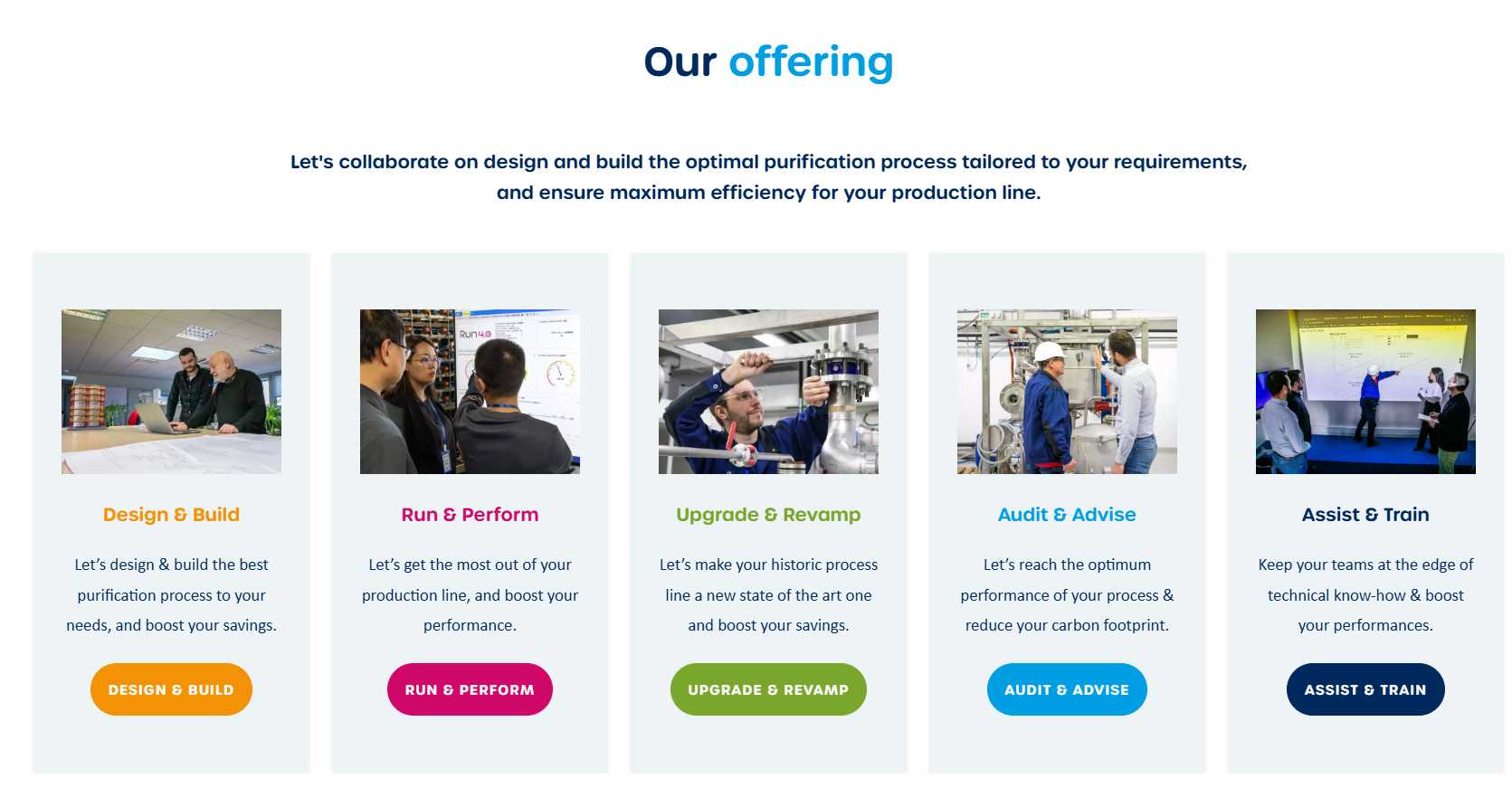

Applexion supports purification excellence across the full equipment lifecycle—from design and commissioning to upgrades, audits, and training. They help sugar mills make purification efficient, sustainable, and future-ready.